You probably wouldn’t know this, but Maine was once the capital of American footwear. It was on the banks of the Androscoggin River that massive factories and tanneries were built that formed the backbone of America’s industrial shoe production in the early 20th century. Today, the few workshops that have survived have done so because they make some of the highest quality and unique footwear in the world. One such company is Rancourt & Co. in Lewiston, Maine.

You may not recognize their name, but you have probably worn shoes made by them for other brands. Partnering with Red Wing on the Genuine Handsewn collection, the shoes are crafted using century-old techniques that have been passed down from generation to generation. With durable, rugged soles and thick leathers that soften and develop the perfect patina with age, you’ll realize there is no substitute for hand-crafted footwear in terms of the quality of materials and construction.

Take a look inside the factory, and then check out the five-step production process below.

Step 1: Assemble The Upper

During this initial phase, the leather is selected and cut to pattern. Fitting and sewing components, like eyelets, are also selected.

Step 2: Prepare The Leather

The second step involves preparing the leather to be sewn by immersing the upper in a mix of hot water and leather conditioner. This softens the hide, making it easier to bend around the last.

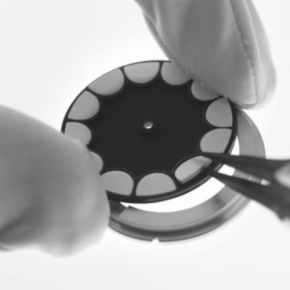

Step 3: Hand Sewing

The upper is tacked and stretched onto the last to give it its initial shoe shape. The plug and vamp are then stitched together using a special coarse, waxed string that is tough enough to hold the leather pieces together, but flexible enough to allow the shoe to stretch and mold to the foot over time.

Step 4: Drying & Attaching

Once stitched together, the upper and last are dried, allowing the leather to form to the shape of the last. After the leather is dry, the bottom of the upper and outsole are prepped and the two are attached. The outsole is then trimmed and buffed.

Step 5: Cleaning & Conditioning

The final step in the process is cleaning and conditioning the upper. Waxes, oils and creams are applied and polished, enhancing the leather’s surface feel. The laces are added and the shoes go through their final inspection.

Blue Bear Outside 5-Panel Cap

Blue Bear Outside 5-Panel Cap Fifty and Fifty: The State Mottos Project

Fifty and Fifty: The State Mottos Project Making It: Ellsworth & Clyde

Making It: Ellsworth & Clyde Kyrie Irving’s Commercial For Foot Locker

Kyrie Irving’s Commercial For Foot Locker Supreme x Nike Air Force 1

Supreme x Nike Air Force 1 This Is Why I Still Buy CDs

This Is Why I Still Buy CDs Akomplice Fall 2012 Collection

Akomplice Fall 2012 Collection Making It: Blunt Umbrellas

Making It: Blunt Umbrellas KICKS/HI x Vans Vault Authentic LX

KICKS/HI x Vans Vault Authentic LX Making It: Lia Neal

Making It: Lia Neal Supreme x Nike SB Dunk Low

Supreme x Nike SB Dunk Low How To Make It Presents: Bardo “Game Tape” Mixtape

How To Make It Presents: Bardo “Game Tape” Mixtape The Ring Maker

The Ring Maker WINWEL Spring/Summer 2012 Collection

WINWEL Spring/Summer 2012 Collection Kanye West Presents: Cruel Summer

Kanye West Presents: Cruel Summer The 100th SNL Digital Short

The 100th SNL Digital Short Making It: Tanner Goods

Making It: Tanner Goods The Making Of: KAWS x Ikepod Horizon Watch

The Making Of: KAWS x Ikepod Horizon Watch Photos: Kate Upton by Terry Richardson

Photos: Kate Upton by Terry Richardson Sneakercube by Pawel Nolbert

Sneakercube by Pawel Nolbert